Quality control

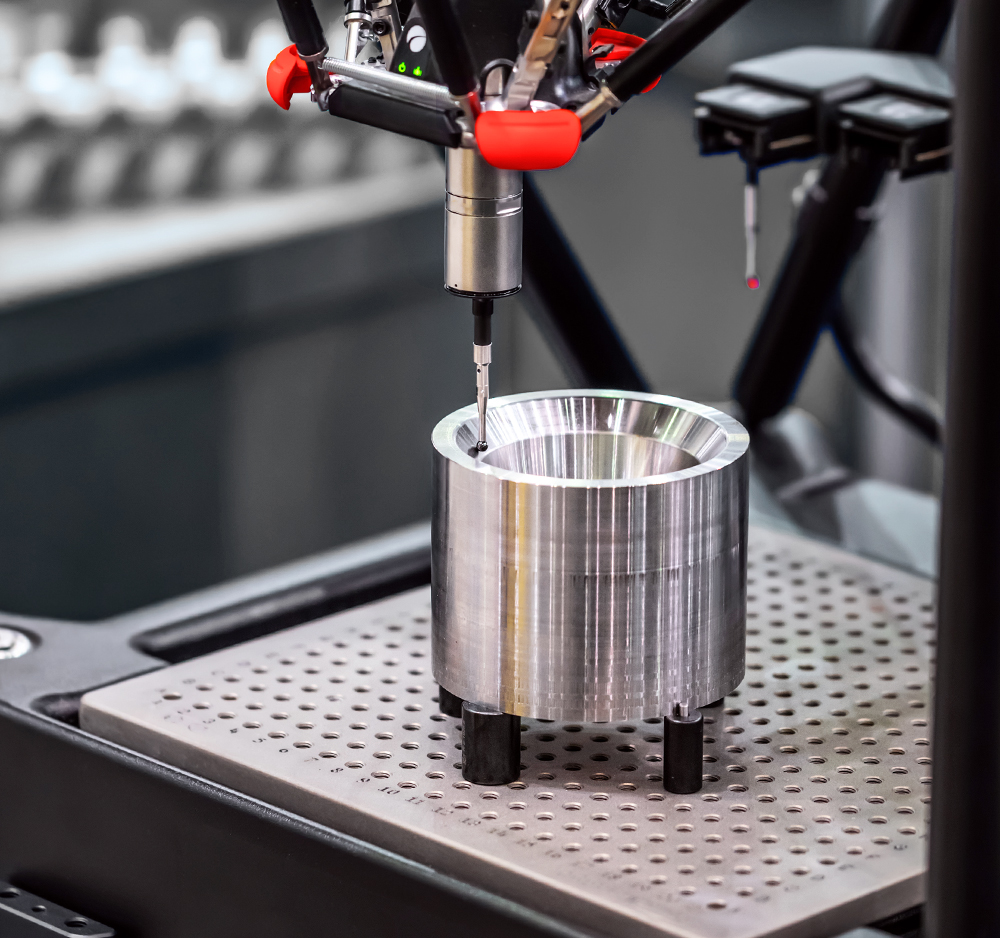

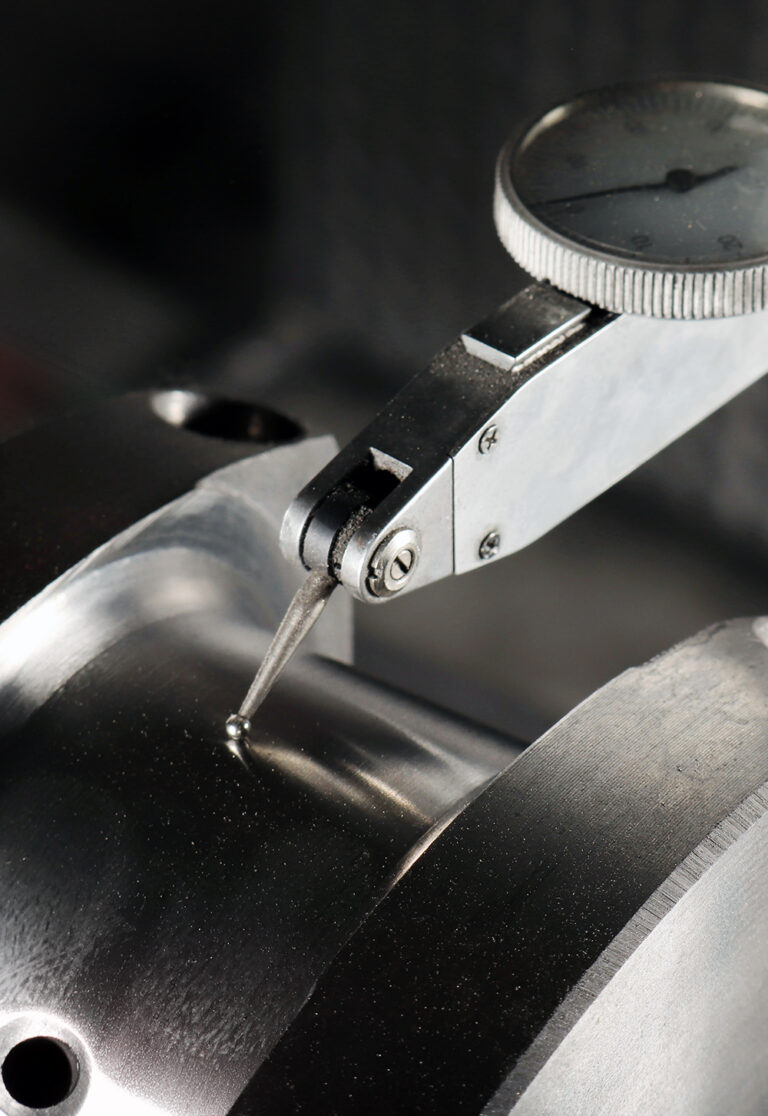

For us at AT4B, quality control is fundamental to the production and delivery of high quality products. We conduct rigorous tests and inspections at every stage of production to ensure that the parts produced comply with the highest standards. Qualified employees ensure the quality of every part and take swift corrective action if any irregularities are detected. State-of-the-art technology and measuring tools ensure accurate and reproducible quality control resultsi.

In our company, we ensure that every production process complies with procedures, ISO standards and the requirements of our customers. Thanks to our ISO certification, customers can be assured that we are applying the best solutions and good practices. Regular quality control ensures that products are manufactured to the highest standard, but it is also a way of continuously improving production processes.

Ensuring the high quality of our products through quality control is a point of honour for us.

Certification + internal control

We always focus on the highest quality and attention to detail. This is why our production processes are carefully controlled and certified according to the latest quality standards. Our employees supervise the work of the machines, taking care of every detail so that the result is products that are not only robust but also precise.

Our ISO certification, confirms that our products meet all industry requirements and standards. In addition to the certification, which we believe is essential, we regularly carry out internal quality checks to guarantee our customers 100% satisfaction with the order they receive. Thanks to a special measuring machine, which is located in a separate part of our machine park, we are able to produce extremely accurate parts in accordance with the documentation entrusted to us. The diligence we put into our daily work results in new realisations and permanent collaborations, not only from Poland, but also from outside the country.